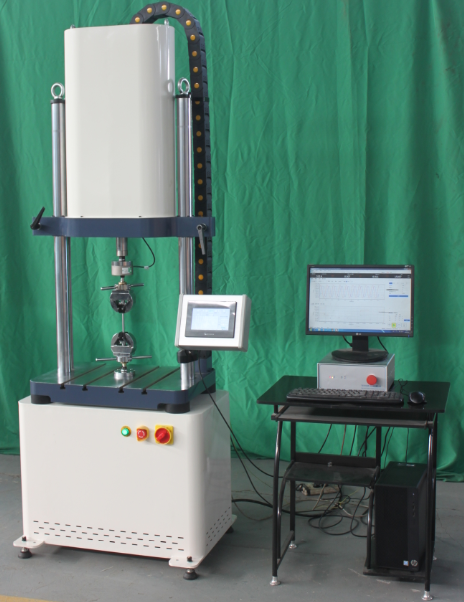

High Speed Tensile Impact Testing Machine is deign for ASTM F2634 − 15 Polyethylene (PE) Butt Fusion Joints using Tensile-Impact Method,

High Speed Tensile Impact Testing Machine

The main difference between the ASTM F2634 − 15 High and ISO 13953 – Determination of the tensile strength and failure mode of test pieces from a butt-fused joint are Four main point

1 The testing speed

ASTM F2634 − 15 Testing speed need 152mm/s for testing the wall thickness less than 1.25 inches, and 102mm/s for testing the wall thickness over 1.25 inches

ISO 13953 Testing speed is 5mm/min for testing all size wall thickness specimens

2 The Specimen size

3 ASTM F2634 need extra Impact Mechanism, The impact load is imparted by allowing 0.25 in. (6.4 mm) minimum free movement of the drive mechanism before applying the load to the specimen .Normally we solve this problem with special design fixture.

4 The sampling rate

ASTM F2634 − 15 need system sample rate at least 1000HZ

ISO 13953 only use the normal tensile testing machine to do the test, normal tensile testing machine sample rate is 50-100Hz

That’s the main different between ASTM F2634 − 15 Polyethylene (PE) Butt Fusion Joints using Tensile-Impact Method and ISO 13953 – Determination of the tensile strength and failure mode of test pieces from a butt-fused joint .

Any question and interested with those equipment please freely to contact us.WWW.UPWELLTEST.COM OR INFO@UPWELLTEST.COM