The waterproof performance of fabrics is mainly divided into the fabric’s resistance to being wetted by water and the fabric’s resistance to water penetration. Characteristic indicators of the waterproof performance of fabrics include water-wetting grade, hydrostatic pressure resistance level, water penetration, etc. The test methods are mainly divided into water-wetting method (spray method) and hydrostatic pressure method.

Problems that often happen during testing

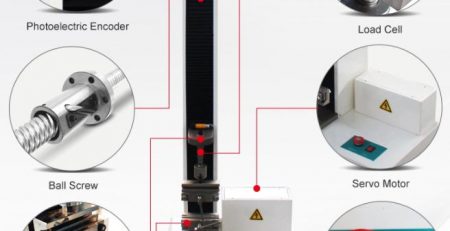

Textile Hydrostatic Head Pressure Test Machine, ISO-811,ISO 1420,AATCC 127

During the hydrostatic pressure test, improper operation may affect the results of the experiment.

The following situations will affect the results of the experiment:

Before clamping the sample, ensure that there is no air between the sample and the water, and then clamp the sample for experimental testing. If there is air between the sample and water during the test, the water will not be completely in contact with the specified experimental area, and water droplets will not appear in part of the sample area, which will affect the experimental

During the test, try to ensure that the edges of the specimen holding device are impermeable and leak-proof. If the sample seeps or leaks at the edge of the clamping device, water will seep out from the edge of the clamping device during the test, and the test pressure of the sample will rise unstablely. This cannot guarantee the accuracy of the experimental results, and will have an impact on experimental results.