Definition of Carbon Black Dispersion

Carbon black Dispersion Tester

Carbon black is a commonly used filler, widely used in rubber, plastic, coating, ink, printing and other industrial fields. The performance of carbon black directly affects the quality and service life of the product, and the dispersion of carbon black is one of the important factors affecting the performance of carbon black. Carbon black dispersion refers to the uniformity of carbon black distribution in the substrate, that is, the comprehensive performance of factors such as the size, shape, quantity and dispersion state of carbon black particles. Good carbon black dispersion can make the filler fully play its role of strengthening, hardening, blackening and toughening.

Test method of carbon black dispersion

Image microscopy: Cut a thin section with a flat surface of the pipe with a blade, soften the section with a constant temperature box, and collect pictures through a microscope. The carbon black dispersion of the pipe is rated by comparing with the standard picture.

Operation steps of image microscopy

- Cut a flat section of the pipe surface with a surgical blade and place it on a slide. Cut a total of 5 samples at different positions. Place it in a constant temperature box and set it to 200℃ for 10-20min;

- Set the calibration file: a. Take a clear ruler picture with a 10X microscope, b. Open the ruler picture on the carbon black dispersion analysis software and select a distance to calculate the proportional factor, which is the calibration file for determination;

Carbon Black Dispersion Tester 2

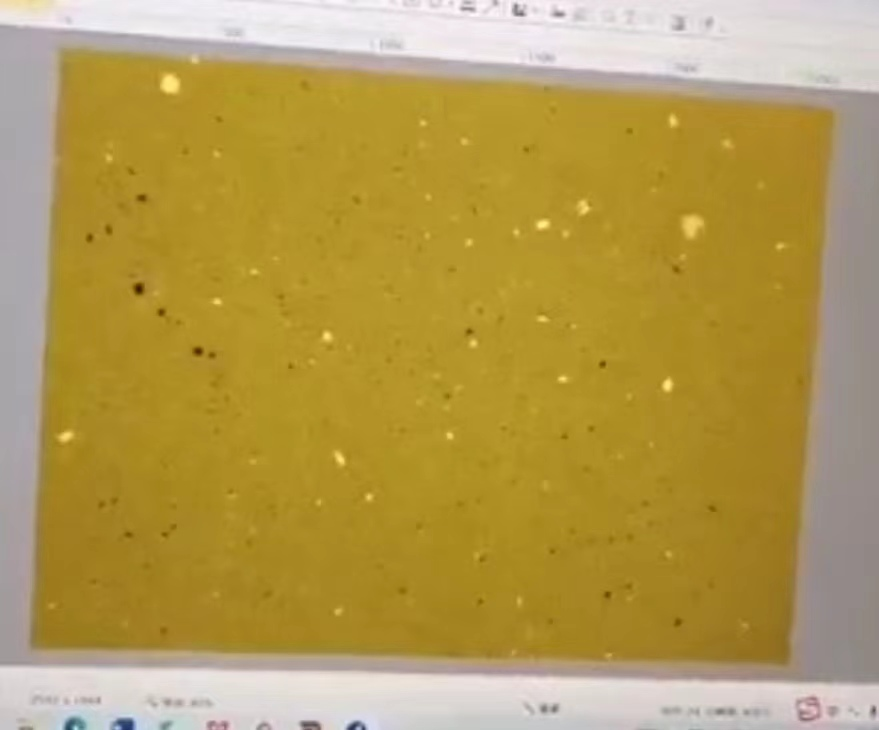

- Take clear pictures of the sample that has been kept at 200℃ with a 100X microscope and save them with different names;

Carbon Black Dispersion Tester 3

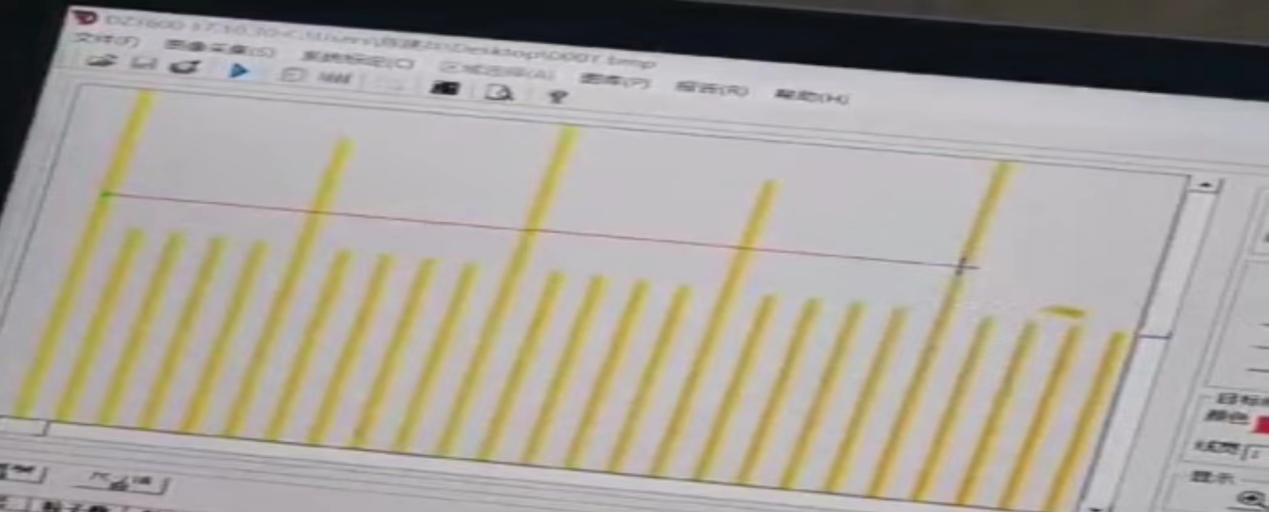

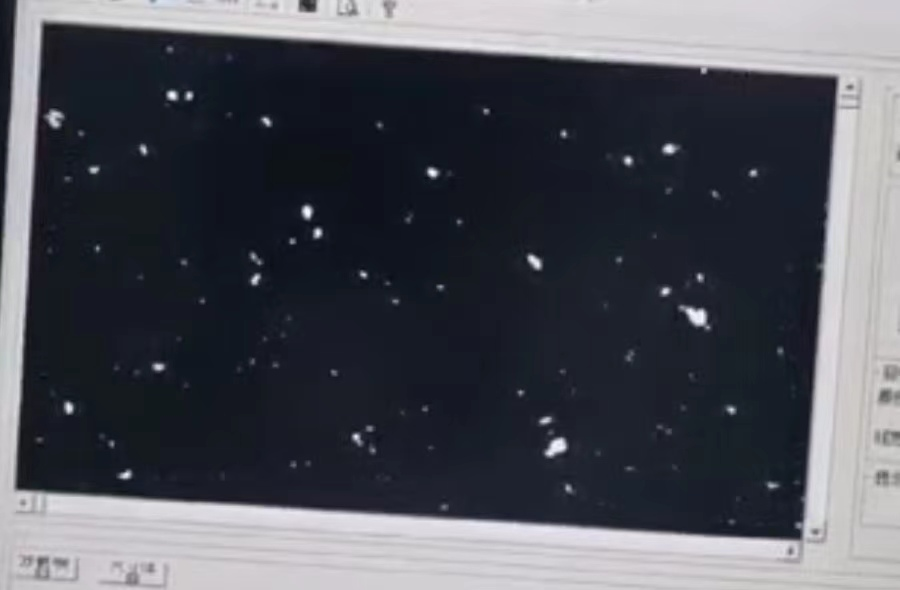

- Open the picture with the carbon black dispersion software and move the field of view to the position with more carbon black particles, then analyze the grayscale distribution and threshold (select the starting point of grayscale rise) of the picture, fill in the threshold and click the level judgment;

Carbon Black Dispersion Tester 4

- Repeat the test and analyze and judge other samples and take the average value.

- Analysis of experimental results

Carbon black content (quality) and carbon black dispersion play a vital role in the weather resistance of pipes. At present, all ISO, EN and standards stipulate that black mixed materials must be used to produce PE100-grade gas pipelines and water supply pipelines. The carbon black content of the mixed material should be carbon black with a particle size of less than 25 nm, the carbon black content should not be less than 2.0%, and the carbon black dispersion should be ≤ level 3.

More Detail please contact us WWW.UPWELLTEST.COM OR EMIAL:INFO@UPWELLTEST.COM