The electronic universal testing machine is an important device for the mechanical research of non-metallic materials. However, there are various models of electronic tensile testing machines, each capable of meeting different measurement needs. Regardless of the type of non-metallic tensile testing machine, errors are bound to occur during measurement. Therefore, people often conduct multiple experiments to finally determine accurate values.

By using the method of multiple experiments, the error rate of the measured values can be avoided, thereby reducing the errors. However, during the measurement process, it is common to encounter both positive and negative differences. So, what should we do if the electronic tensile testing machine shows positive or negative differences during measurement? Below, we provide a detailed introduction to the solutions for positive and negative errors in electronic universal testing machines.

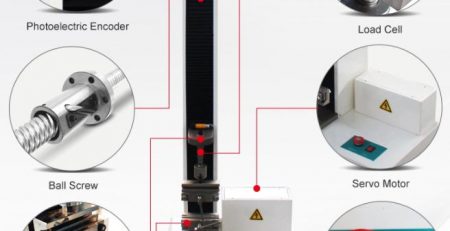

Electronic universal testing machine

1 When the electronic universal testing machine is being calibrated and shows positive or negative errors, generally, the displayed value of the testing machine is corrected against the corresponding standard force value. However, it is important to note that any manual corrections should not be made arbitrarily but should be adjusted based on the actual situation.

2 When the measurement error is a negative error and is linear, first, during calibration, the actual error values at each verification point should be recorded. Then, during the next calibration, the standard force value at each calibration point will be the standard force value minus the actual error value, so it can be adjusted. For example, if the standard force value is 200 kN and its error is -4.2 kN, when the display shows 195.8 kN during calibration, you should confirm the key and input the value.

3 When the measurement error is a positive error and is linear, using the method for negative errors, during calibration, the standard force value at each calibration point should be the standard force value plus the actual error value; then input it, which can also be adjusted.

4 If the measurement error, whether positive or negative, is not linear, the above method can be used for calibration, and then conventional calibration methods can be applied to achieve the adjustment.

In fact, the errors that occur in the measurements of the electronic universal testing machine can be adjusted using the methods mentioned above, regardless of the type of error. If you encounter any of these error issues during measurement, you can use these methods to solve them. However, it is still essential to pay attention to data recording during measurement and not overlook detail-related issues.

Any interested please contact us :info@upwelltest.com or www.upwelltest.com