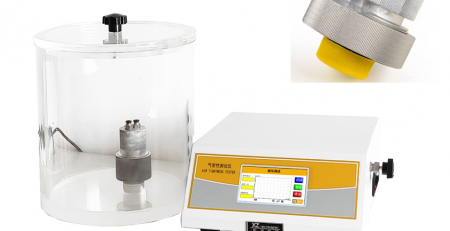

The plastic melt flow index tester is an instrument used to measure the melt flow rate of thermoplastics at a certain temperature and pressure. This test is essential for evaluating the processing performance of materials and can help manufacturers optimize production processes to improve product quality.

In the plastics industry, the quality of raw materials directly affects the performance of products. Melt flow index (MFI) is an important indicator for measuring the flow performance of plastic melts, which reflects the fluidity of plastics under specific conditions. By using the plastic melt indexer for measurement, the quality of raw materials and processing technology can be effectively controlled, thereby improving the overall quality of products. Usually, the heating and melting method is adopted. Under the specified temperature and load conditions, the plastic melt is allowed to flow out of a capillary of a standard diameter, and the mass or volume of the plastic flowing out within a specified time is measured. The higher the MFI value, the better the fluidity of the plastic melt.

Plastic Melt Flow Index Tester

Application value

- Raw material quality control: By regularly testing the MFI value of different batches of raw materials, the consistency and stability of the raw materials are ensured, which is essential to ensure the stability of product performance.

- Process parameter optimization: The MFI value is closely related to factors such as processing temperature and pressure. By monitoring the MFI value, the process parameters such as the screw speed and die temperature of the extruder can be adjusted to obtain the processing effect.

- Product performance improvement: For applications that require good fluidity (such as films and fiber products), by selecting the appropriate MFI value material, the physical properties such as transparency and strength of the product can be improved.

- Fault prediction and prevention: Abnormal MFI values are often a precursor to equipment problems or raw material deterioration. Timely detection and treatment of these problems can avoid downtime losses in the production process.

Implementation steps

- Establish a standardized test process: Develop detailed test operating procedures based on relevant international standards such as ISO or ASTM to ensure the accuracy and comparability of each test result.

- Regularly calibrate the instrument: In order to ensure the accuracy of the test results, the melt indexer needs to be calibrated and maintained regularly.

- Data recording and analysis: After each test, the test conditions and results should be recorded in detail, and statistical analysis should be performed to facilitate the discovery of problem trends.

- Continuous improvement: Based on the results of data analysis, process parameters and technical solutions are continuously adjusted to achieve continuous improvement of product quality.

As one of the key testing tools in the plastics industry, the plastic melt index meter can not only help manufacturers improve the efficiency of raw material selection, but also achieve refined management in the production process to achieve the goal of improving product quality.

Any interested or question please contact www.upwelltest.com or email:info@upwelltest.com