The coefficient of friction refers to the ratio of the friction between two surfaces to the vertical force acting on one of the surfaces. It is related to the roughness of the surface, but not to the size of the contact area. According to the nature of the movement, it can be divided into the dynamic friction coefficient and the static friction coefficient. Sliding friction is generated when two objects contact each other and slide relative to each other.

The coefficient of friction is an indicator to measure the sliding characteristics of flexible packaging materials. It is very important for the film packaging process that the surface of the film material is smooth and has an appropriate friction coefficient. The value of this indicator will directly affect the convenience of the packaging material during use. This article mainly introduces the test principle and method of the coefficient of friction.

Reference standard: ISO 8259 Plastics Film and sheeting Determination of the coefficients of friction

Test principle: Two experimental surfaces are placed flat together, and under a certain contact pressure, the two planes are moved relative to each other, and the required force is recorded. The friction coefficient value is the test force divided by the normal force.

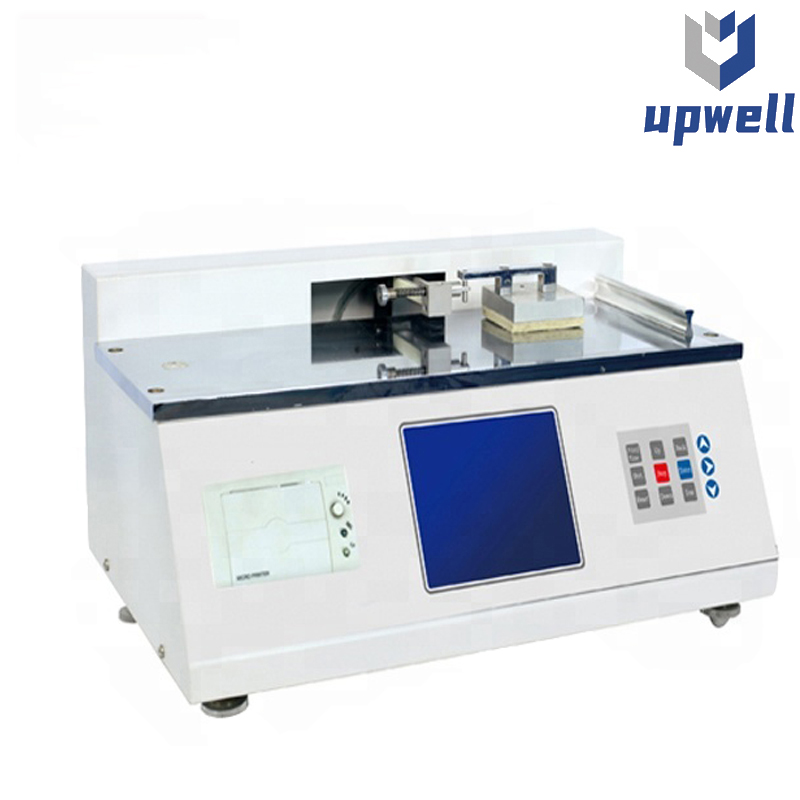

When it comes to the coefficient of friction, there must be a special instrument for measuring the coefficient of friction. The friction coefficient tester developed and produced by JINAN UPWELL TECH is designed and manufactured in strict accordance with ISO 9259 standards. It is professionally used to measure the static friction coefficient and dynamic friction coefficient of plastic films and sheets, rubber, paper, cardboard, woven bags, fabric styles, metal composite belts for communication cables and optical cables, conveyor belts, wood, coatings, brake pads, wipers, shoe materials, tires and other materials when sliding. By measuring the smoothness of the material, the quality process indicators of material production can be controlled and adjusted.

ASTM D1894, ISO8295 PET Films Coefficient of Friction Tester

Below we take the paper aluminum plastic composite film material as an example to explain the test method of the friction coefficient:

1) Take 3 pieces 8cm×20cm samples. The test surface requirements should be flat, without wrinkles and scars that may change the friction properties. The edges of the sample should be smooth. The test surface of the sample should be dust-free.

2) Conditioning of the sample state and standard environment for the test. Condition the sample state for at least 16 hours under a standard environment with a temperature of 23±2℃ and a relative humidity of 45% to 55%, and then conduct the test under the same environment.

3) System calibration: The new machine should be calibrated and zeroed before use, and zeroed from time to time.

4) Sample clamping: Clamp the sample with the instrument on the right side and fix it flatly on the instrument panel; put the test surface of the other sample downward, wrap the slider, fix it on both sides of the slider with tape, and place it in the center of the sample without impact.

5) Parameter setting, then start the test.

6) The experiment is over and the experimental results are obtained: This process is all automatically controlled, and the test process is displayed in real time.

The results show that the friction direction has little effect on the friction coefficient. In actual production, the main consideration is the effect of the friction substrate on the friction coefficient.

Any interested please contact us www.upwelltest.com or email:info@upwelltest.com