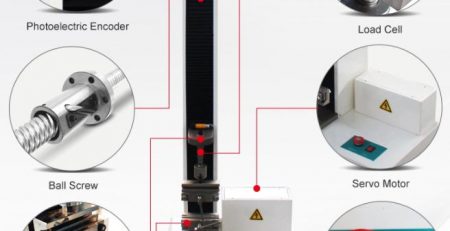

Differential Thermal Gravimetric Analyzer, TGA Thermogravimetric Analyzer is an instrument that uses the thermogravimetric method to detect the temperature-mass change relationship of substances. The thermogravimetric method is to measure the relationship between the mass of a substance and the change of temperature (or time) under programmed temperature control. When the measured substance sublimates, vaporizes, decomposes out of gas or loses crystal water during the heating process, the quality of the measured substance will change.

THERMO GRAVIMETRIC ANALYZER(TGA)

Common problems encountered by differential Thermal Gravimetric Analyzer:

- The problem of sample holder falling off

Carefully observing the structure of the TGA Thermogravimetric Analyzer, it is not difficult to find that there is a high-temperature-resistant and corrosion-resistant gel-like material that acts as a bond between the tripod of the balance and the thermocouple. The detachment of the sample holder is often caused by the destruction of the adhesive. Although the material used for the adhesive is high temperature resistant, when the test sample is heated up at high temperature (above 700°C) for a long time or kept at a constant temperature, the adhesive will also be damaged, causing the sample holder to fall off. The sample crucible cannot be placed stably in the holder, and it will shorten the life of the heating wire.

- Whether the exhaust pipe of the furnace cover and the balance bracket are clean

Usually, after the instrument has been used for a period of time, some black smoke and dust will adhere to the furnace cover and the inside of the exhaust pipe. Driven by the airflow, it may fall into the balance bracket in the furnace or the furnace body, which will affect the accuracy of the balance test. Therefore, it is necessary to clean the furnace cover and exhaust pipe regularly to prevent pollutants from accumulating or falling into the furnace and ensure the accuracy of the analytical balance measurement.

- For long-term sample testing, some decomposed residues of the sample will slowly adhere to the support rod, which will affect the test accuracy of TG. Therefore, it is necessary to regularly fire the support rods at high temperature in an air or oxygen atmosphere to 800°C. The cooling section can be increased but the high temperature and constant temperature cannot be used! Generally once a week, the specific situation is determined according to the frequency of sampling and the contamination of the instrument, so as to remove the residue on the bracket and improve the accuracy of TG testing.

Any question or interested please contact us www.upwelltest.com or email us :info@upwelltest.com