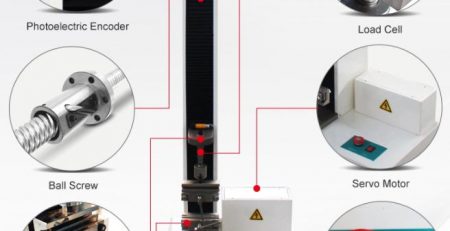

Tensile testing machine is also called universal material testing machine or tensile machine. It adopts mechatronics design and consists of main part, mechanical part, hydraulic system, force measurement system, etc. The force measurement system is mainly composed of force sensor, transmitter, micro The processor, load drive mechanism, computer and color inkjet printer constitute.

Tensile testing machine Application

Tensile testing machine can be used for tensile test of mesh rope, textile, metal rod, waterproof material, rubber, wire and cable, plastic, metal wire, and other materials, and additional accessories can be used for compression and bending tests. It has the functions of digital display of test force, continuously adjustable test speed, automatic shutdown when the sample is broken, and peak value hold.

Installation, use precautions and maintenance of tensile testing machine

The tensile testing machine should be installed in a clean, dry, vibration-free room with a room temperature of 20℃±10℃, and it should be noted that sufficient space should be left around the testing machine for beam bending tests, test with extensometers, and equipment maintenance. Free area.

- Installation

The main body and the dynamometer of the tensile testing machine should be installed on the concrete foundation. The basic dimensions should be based on the shape and foundation plan. The foundation screws, the lower jaw screw holes and other devices such as wire installation pipes should be reserved. The upper plane of the foundation should be flat, use a level to straighten it, and after the foundation is dry, install the testing machine.

① Installation of tensile testing machine and preliminary accuracy alignment

Transport the main body and the dynamometer to the concrete foundation separately, adjust the distance between the main body and the dynamometer and adjust the direction according to the shape and foundation plan, and then insert the main body and the dynamometer respectively with a thin piece of iron The bottom part (between the foundation) of the bottom part is aligned separately with a 0.05/1000 precision square level gauge. The preliminary alignment of the main body can be measured with a square level gauge at two different positions of the vertical and horizontal positions of the two columns, and the plumbness shall not be greater than 0.3/1000. Then, the square level gauge can be used to lean against the vertical and horizontal positions of the outer surface of the cylinder to align it. Plumbness.

②The accuracy of the tensile testing machine is adjusted

After the above preliminary accuracy calibration of the testing machine, connect the oil pipe, power supply and oil filling to perform preliminary operation test. When the test conditions are good, perform the accuracy calibration of the testing machine. Use a square horizontal instrument to lean on the work platform, align the plumbness of the oil cylinder, adjust or increase or decrease the shim under the base, so that the error should not be greater than 0.10/1000. After the accuracy of the testing machine is determined, all the gaps under the machine base are filled with cement slurry to keep the machine base and the cement foundation well combined to prevent the testing machine from being out of level due to vibration during use. After the anchor nut is poured, it is not allowed to fasten the anchor nut and start the testing machine before the cement is dry. (Cement drying time is generally not less than 10-15 days) After the cement is completely dry, tighten the good luck foot nut, and recheck the installation accuracy of the testing machine to see if it is consistent with the alignment accuracy. If it does not meet, it should be re-aligned. During the use of the tensile testing machine, because the vibration during the test is prone to loosening, the relevant parts should be tightened after the tensile testing machine is used for a period of time.

- Takeover

When installing the oil pipe connecting the main body and the dynamometer, the inside of the oil pipe should be cleaned with kerosene to ensure the cleanliness of the oil circuit. Attention should be paid to the integrity of the gasket at the joint to prevent oil leakage under high pressure.

- Selection of oil specifications

In hydraulic rotation, N68 precision machine tool hydraulic oil can be used, or other similar specifications of oil can be used. Its kinematic viscosity (100℃) is 11-14 centistokes.

- Oil filling and draining

Open the air filter on the fuel tank and fill the fuel tank with oil. The amount of fuel injected at a time is about 24 kg. For the specifications of the oil used, please refer to the specifications of the oil. When draining the oil, just open the oil nipple at the bottom of the left side of the dynamometer. The service life of the oil is determined according to the local climate. If the oil is found to deteriorate or become dirty, it should be replaced with a new one.

- Power up

The electrical device of the tensile testing machine is in the dynamometer. The power supply is a three-phase four-wire system. The circuit between the main body and the dynamometer is connected by a plug. The dust and other impurities in the electrical box should be cleaned before power on. After the power cord, press the “Power” button on the dynamometer panel and the indicator light is on to prove that the power supply has started. At this time, press the oil pump start button to observe the motor rotation direction, and then press the jaw base lifting button to check the lower jaw base. Whether the lifting action is consistent with the text shown on the button, and at the same time check whether each limit switch is working.

- Lubrication

Lubricating oil can be poured on the screw of the lower jaw to lubricate the screw and the screw nut. There is an oil filling hole on the base, which is to inject the oil into the oil to lubricate the worm. The scale of the oil in the oil can be measured. As measured by the oil needle, the maximum oil level of the oil stick does not exceed the lower flat part of the oil needle. The lower end of the oil stylus is the lowest oil level in the oil stick.

- Initial operation and commissioning of the oil pump

Press the button on the dynamometer table to start or stop the oil pump. When operating for the first time after installation or changing the wire joints, check whether the oil circuit of the oil pump is unblocked.

- Safety device

The main cylinder and hydraulic chuck of the tensile testing machine are equipped with protection relief valves and limit switches.

- Matters needing attention during operation

① If the oil pump suddenly stops working during the test, the load should be removed at this time to reduce the oil pressure, and the oil pump should be restarted for the test after inspection. The oil pump should not be started under high pressure or the cause of the accident should not be checked.

② If the electrical appliance fails while the tensile testing machine is working, and the start or stop button does not work, the power supply should be cut off immediately to stop the testing machine.

③It is forbidden for non-operating personnel to operate on the machine.

- Maintenance of tensile testing machine

All parts of the tensile testing machine should be wiped clean frequently. After wiping the ones that are not painted, wipe them with cotton yarn and a small amount of oil to prevent rust. During the rainy season, they should pay attention to wiping. When not in use, use a dust cover to prevent dust intrusion. . After each test, the test bench should be lowered. It is best not to drop the piston to the bottom of the cylinder and leave a little distance to facilitate the next use. All the valves on the dynamometer should not be opened to prevent dust from entering the interior and affecting the sensitive performance of the measuring mechanism. The oil pump motor should be turned off when the test is suspended.

Any more question please freely to contact us www.upwelltest.com