Fabric Martindale Abrasion Wear Tester is a quality testing equipment widely used in the textile industry. It is mainly used to test the wear resistance and abrasion properties of fabrics. Based on the principle of tribology, the wear resistance and abrasion performance of the fabric are evaluated by simulating the contact between the fabric and other materials in different environments. The equipment consists of a drive system, a load system, a counter and a data acquisition system. Among them, the driving system keeps the sample and the wear body in relative motion, the loading system applies a certain pressure to load the sample, and the counter and data acquisition system record and analyze the data during the wear process.

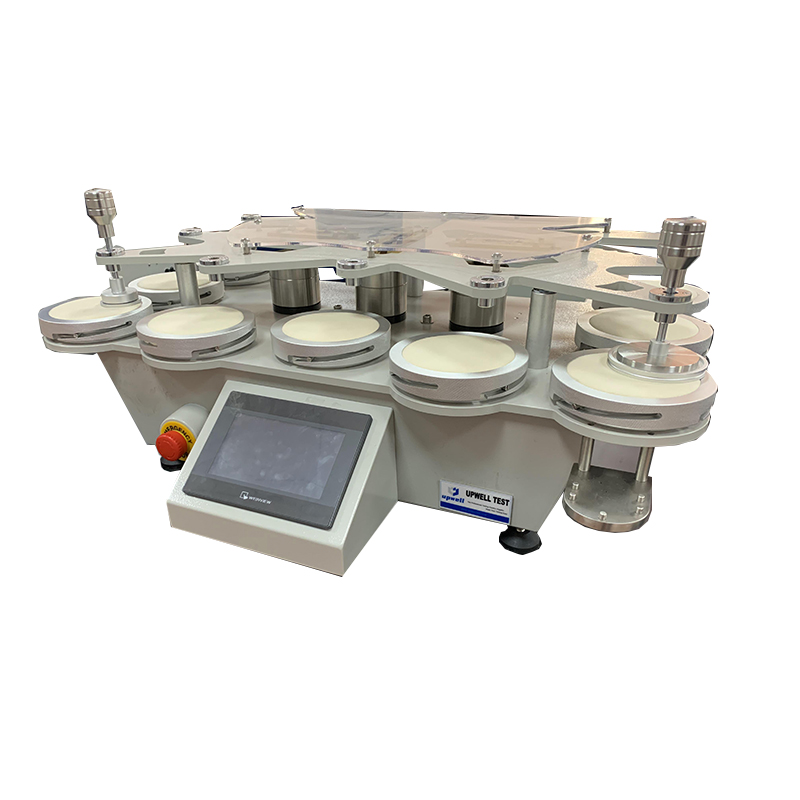

Martindale Fabric Abrasion Tester

Test items and methods:

Wear resistance test: This test item is mainly used to evaluate the wear resistance of fabrics. It is widely used in fabric wear resistance testing. It is evaluated by simulating the friction between fabrics and other materials under specific conditions and measuring the number of wears or the wear area. The wear resistance of the fabric.

Abrasion performance test: This test item is mainly used to evaluate the sliding performance and surface friction coefficient of fabrics when in contact with other materials. Common testing methods include roller method, flat plate method and rotary method. By applying a certain load and simulating actual use conditions, the mechanical properties and surface friction coefficient of the sample during the sliding process are measured to evaluate the friction properties of the fabric.

Application of fabric Martindale friction and wear tester in textile industry:

Product development and improvement: The wear resistance and Abrasion performance of fabrics can be evaluated during the product development stage to provide designers with data support to optimize product structure and material selection. At the same time, the equipment can also be used to improve the quality of textiles and improve the durability and comfort of textiles by testing and comparing different materials and processing techniques.

Quality control and standard setting: It can be used in textile enterprises for quality control and standard setting. By testing samples from different batches and different processes, it can be judged whether the wear resistance and friction performance of textiles meet the requirements, and corresponding quality standards and technical specifications can be formulated.

Dispute resolution and technical support: In the textile industry, it can also be used for dispute resolution and technical support. When quality problems or disputes arise, by testing the fabric involved, its wear resistance and friction properties can be objectively evaluated, providing a scientific basis for dispute resolution. At the same time, the equipment can also provide technical support and consulting services to textile enterprises to help solve problems and problems in the production process.

As an important textile quality testing equipment, the fabric flat grinder has the function of evaluating the wear resistance and friction properties of fabrics. By rationally utilizing this equipment, textile companies can effectively improve the competitiveness and quality of their products and meet market demand. At the same time, it plays an important role in quality control, product development and technical support, and contributes to the development and progress of the textile

Any interested or question please contact us info@upwelltest.com or www.upwelltest.com