The melt flow index meter is in charge of a special person. The test should be carried out in strict accordance with the operating procedures. It is strictly forbidden to do tests beyond the test range. After the test, the instrument should be restored to its original position to ensure that the next test is carried out normally. The working environment and conditions should meet the The specified requirements include relative humidity, room temperature, power supply voltage, and installation basis. Generally, there is no vibration, no corrosive medium, and no strong electromagnetic field interference around the machine. In addition, some instruments have special requirements for the environment, and should strictly follow the instruction manual. Carry out maintenance and maintenance; when the melt indexer is not used for a long time, it should be plugged in regularly. Before and after using the melt indexer, it should be kept clean and avoid collision. The melt indexer should be cleaned and inspected regularly, and the instruments to be calibrated should be calibrated. to ensure the accuracy of the instrument. When not in use, appropriate protective measures should be taken. If it is not used for a long time, it should be re-inspected before use.

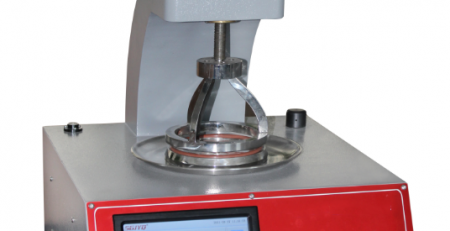

Melt Flow Index Tester(MFR)

The equipment should be placed stably and the ground on which it should be placed should be firm. When the equipment is in use, the shell should be connected to the protective ground wire, and the equipment shell should be connected to the ground to protect the safety of operators and equipment. After using the equipment, turn off the power of each part of the system, and do not plug and unplug the power cord with power on, and connect to the equipment according to the specified power supply voltage. Make sure the circuit is wired correctly. Otherwise, the device will be damaged. It needs to be placed indoors. The laboratory should be clean, dry and non-corrosive medium. Non-related personnel should not operate at will, and the equipment cable should not touch the sharp edge, so as not to scratch the cable insulation; do not pull objects with cables or bundle objects with cables , so as not to break the cable so that the equipment cannot operate normally, and do not let the cable be pressed under heavy objects, so as not to cause a fire by breaking the cable.

During the test, unrelated personnel should not be allowed to approach, because the automatic melt indexer can generate high voltage, and personnel without training cannot use the equipment. There should be a guardian during the test, and it should not be used by one person. In case of an accident, if the equipment is not used for a long time, when using it again, the instrument should be pressurized once without load, that is, the wiring of the high-voltage electrode should be removed from the pressure equalizing ball.

More detail please contact www.upwelltest.com or eamil:info@upwelltest.com