Textile Jigger Dyeing Machine

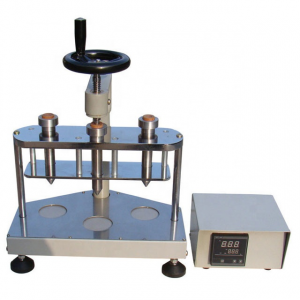

Textile Jigger Dyeing Machine is suitable to test the dyeing of cotton and linen cloth, viscose, man-made fiber, etc., and suitable for dye material, such as direct dyes, acid dyes, basic dyes, insoluble azo dyes, and reactive dyes, etc. This apparatus can achieve bleaching and dyeing with low-liquor ratio, simulates as nearly as possible the mechanism of production jigs.

- Description

- Inquiry

Application:

Textile Jigger Dyeing Machine is suitable to test the dyeing of cotton and linen cloth, viscose, man-made fiber, etc., and suitable for dye material, such as direct dyes, acid dyes, basic dyes, insoluble azo dyes, and reactive dyes, etc. This apparatus can achieve bleaching and dyeing with low-liquor ratio, simulates as nearly as possible the mechanism of production jigs.

Textile Jigger Dyeing Machine is specially designed to satisfy the requirements of testing dye formula before quantity production of dyeing and finishing enterprise. This apparatus simulates as nearly as possible the mechanism of production jigs’ requirements of speed, temperature, pre-tension, etc. of real production process. Compared with production machine, this Laboratory Jig Dyeing Machine’s size is smaller, consumes small quantity of dye, and with short testing process, so operator is easier to change dye formula, and finds suitable dye formula in a short time. Therefore this machine is well welcomed by many dyeing and finishing enterprise.

Features:

1 Operating Interface: Color touch screen man-machine interface, operate easily, programmable function, presetting

dyeing technics for customer;

2 Constant Fabric Speed: Adopt advanced electronic encode control speed technology to precise control of cloth speed,

and maintains a constant cloth speed real-timely;

3 Temperature Control and Monitor: Adopt out-heating technology,avoid heating unevenness, automatic temperature

control system monitors dyes solution’s temperature accurately, and display the temperature on panel digitally;

4 Fabric Tension: Exert tension on cloth by adjusting different linear speeds of two main rollers, and maintain constant

tension, tension value direct input by color touch screen, adjusts speed automatically;

5 Motor: 2 sets 120W precision-controlled motors, and equipped with high quality reducer;

6 Controller: Industrial Programmable Logic Controller(PLC), high reliability, and advanced anti-interference ability;

7 Structural Design: Modular design, convenient for precision production and properties expanding, specially designed

cloth-leading structure, facilitate and smart, easy to install and dismantle;

8 Dye Vat: Imported SUS304 stainless steel, avoid rust, durable; ladder structure, consume small quantity dyes solution;

9 Dyes Solution Cycle Mode: Auto-stirring, keep dyes solution evenness;

10 Winding Length: Automatically records, pre-settable, measurable and controllable;

11 Alternating Direction: Reverse automatically according to cloth length and number of cycles;

12 Timing: Adjustable, end of cycle alarm.

Key Specification:

| Roller Diameter | 76mm~ 200mm |

| Roller Width | ≤450mm |

| Main Roller Distance | 380mm |

| Speed Range and accuracy | 0~10m/min, ±0.001 m/min |

| Heating temperature and accuracy | room temperature~98°C, ±2°C |

| Heater Power | <1.2kW |

| Liquor Volume | about 1.8 liter |

| Electric Load | about 1.5kW |

| Power Supply | 220V, 1 phase, 50Hz |

| Dimensions | 910mm×720mm×900mm(L×W×H) |

| Weight | about 45kg |

| Textile Jigger Dyeing Machine | JR350 |