Charpy impact testing machine is a commonly used material testing machine, which is mainly used for impacts of non-metallic materials such as hard plastics (including plates, pipes, and plastic profiles), reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, and electrical insulating materials. The determination of toughness is an ideal test equipment for the chemical industry, scientific research institutions, quality inspection departments of colleges and universities.

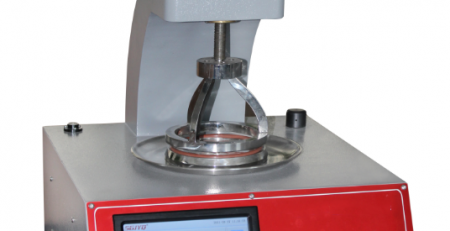

Impact Testing Machine

The working principle of charpy impact testing machine is: a pendulum of known energy is used to hit the sample supported by the horizontal beam, and the sample is destroyed by one impact of the pendulum. The impact line is located in the middle of the two brackets, and the energy difference between the front and rear swings is used to determine the energy absorbed when the sample ruptures. Then calculate the impact strength based on the original cross-sectional area of the sample.

Operation method of charpy impact testing machine:

- Before the test, replace the appropriate pendulum according to the requirements of the impact energy.

- Turn on the power switch device, hold the operator to an empty one (not a sample), check whether the passive needle is pointing to zero, if not, the position of the empty pointer should be adjusted, and the hour and empty pointers are zero. Before resetting the display data of the electronic test instrument, adjust the equipment.

- Excluding the bearing on the edge of the pendulum block, the gap has the influence of the notch support across the center of the specimen, such as the influence of notch tension.

- Press the “Start” button to promote the pendulum, set high and stable on site, the pendulum has been installed on the ship cleaning machine to circle all obstacles, and the largest energy scale dial pointer.

- The simply supported beam impact tester presses the “Test” button, hammers off the sample, and after the pendulum stops swinging, write down the impact of energy. After the test is over, turn off the power operation and the influence of the machine’s power supply, bringing the operator back to the place.

- Specific test steps:

Raise the impact hammer to angle α (150) and fix it on the fixed hook. The pointer is close to the lever, and the pointer should display 150 at this time. Press the fixed hook to make the impact hammer fall freely and push the sample. The reading index indicates the β angle and records. Without the sample, the hammer will be affected from the angle of Alpha, the reading pointer indicates the sum of the angle of α. There is no sample, because the β angle will affect the drop of the hammer, read the angle β indicated by the pointer and record. Without the sample, the impact from the angle α will be hammered. Do not move the cursor, make the impact hammer fall freely, the pointer will rise again, and so on, until the index no longer moves; record the angle θ indicated by the index and record.