As an important equipment for testing the mechanical properties of materials, the standardization of operation and the timeliness of maintenance of the horizontal tensile testing machine are directly related to the accuracy of the test results. Therefore, mastering the correct operation methods and maintenance skills is crucial to ensure the normal operation of the testing machine and the reliability of test data.

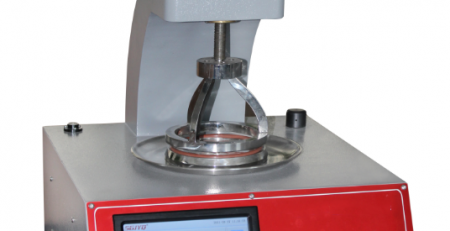

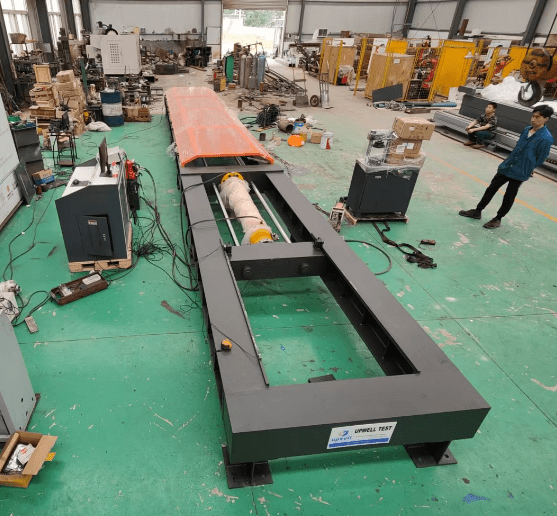

horizontal tensile testing machine

When operating a horizontal tensile testing machine, you must first be familiar with the basic structure and working principle of the equipment. Understanding the functions and roles of each component will help the operator to control the test process more accurately. At the same time, the operator needs to correctly set the test parameters, such as loading speed, test temperature, etc., in accordance with the requirements of the equipment manual to ensure the consistency and comparability of the test conditions.

In addition to operating specifications, equipment maintenance is also the key to ensuring test accuracy. Regularly cleaning the outer shell and internal components of the testing machine can effectively prevent dust and dirt from affecting the performance of the equipment. At the same time, the electrical system and mechanical components of the equipment should be checked regularly to ensure that they are in good working condition. For wearing parts and consumables, such as fixtures, sensors, etc., they should be replaced in time to avoid affecting the accuracy of the test results.

In addition, equipment calibration is also an indispensable part of maintenance work. Regularly calibrating the test machine can ensure that its measurement accuracy meets the standard requirements. During the calibration process, pay attention to selecting appropriate calibration methods and standard parts, and strictly follow the calibration procedures to ensure the accuracy and reliability of the calibration results.

During the operation process, operators also need to pay attention to safety issues. Comply with the equipment’s safe operating procedures, wear protective equipment, and ensure personal safety. At the same time, pay attention to the operating status of the equipment at any time. If any abnormal situation is found, stop the machine for inspection in time to avoid equipment damage or distortion of test data.

Any intesterested or question please contact www.upwelltest.com or email :info@upwelltest.com