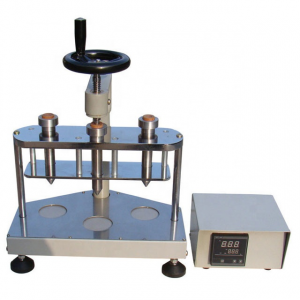

BS 6526 Glove Insulation Tester

It is used to detect the thermal insulation performance of thermal insulation materials at the moment of contact with high temperature.

- Description

- Inquiry

Introduction:

It is used to detect the thermal insulation performance of thermal insulation materials at the moment of contact with high temperature.

Principle:

The palm material of the insulated glove is placed on a polyethylene plate equipped with thermocouples connected to temperature recording equipment. A heated brass cylinder is placed on the sample and the temperature rise is measured over a certain period of time.

Standards compliant:

BS 6526:1998 and other standards.

Features:

1. Color touch screen display, control, Chinese and English interface, menu operation mode.

2. The core control components use ST’s 32-bit multi-function motherboard and 16-bit high-precision temperature acquisition AD chip.

3. It is driven by servo motor and servo controller.

4. The online computer automatically displays the curve.

5. Automatically generate test reports.

6. Brass cylinder release: press the sample down with free gravity.

7. Brass cylinder return: automatic return.

8. Thermal insulation board: automatic movement.

9. Insulation protection board: automatic return.

10. Use omega imported sensors and transmitters.

Parameter:

1. Sample size: 70mm in diameter

2. Temperature range: room temperature +5℃~180℃

3. Temperature accuracy: ±0.5℃

4. Temperature resolution 0.1℃

5. Polyethylene sample mounting plate: 120*120*25mm

6. Sample plate sensor range: 0 to 260 degrees, accuracy ±0.1%

7. Heating block sensor range: 0~260 degrees, accuracy ±0.1%

8. Brass cylinder weight: 3000±10g

9. Brass cylinder size: small head diameter Φ32±0.02mm height 20mm±0.05mm

Big head diameter Φ76±0.02mm height 74mm±0.05mm

10. The detection point of the brass cylinder sensor, the distance from the bottom surface of the brass cylinder: 2.5mm±0.05mm

11. Brass cylinder release speed 25mm/s (speed adjustable from 1 to 60mm/s)

12. Brass cylinder return speed 25mm/s (speed adjustable 1~60mm/s)

13. Distance between brass cylinder and sample surface: 100mm±0.5mm

14. Polyethylene protective plate: 200×250×15mm

15. The distance between the polyethylene protective plate and the upper surface of the sample: 50mm

16. Movement speed of polyethylene protective plate: 80mm/s

17. Time measurement range: 0~99999.9S

18. Power supply: AC220V, 50Hz

19. Dimensions: 540×380×500mm (L×W×H)

20. Total weight: 40kg