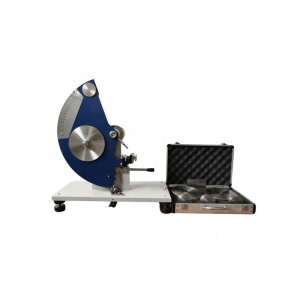

ISO 105 Scorch Sublimation Tester

Scorch Sublimation Tester is used to determine the color fastness to hot pressing and dry heat and to conduct sublimation tests. Providing controlled conditions of dry heat and pressure with top and bottom heated surfaces, electronic temperature controller and carefully controlled top plate weight.

Related Testing Standard:ISO 105-P01, 105-X11 AATCC 114, 117, 133JIS L0850, L0879

- Description

- Inquiry

Application:

Scorch Sublimation Tester is used to determine the color fastness to hot pressing and dry heat and to conduct sublimation tests. Providing controlled conditions of dry heat and pressure with top and bottom heated surfaces, electronic temperature controller and carefully controlled top plate weight.

Features of scorch sublimation tester:

l Equipped MCU to control time and temperature, with over-temperature safety function to shutdown the unit in case of over-heating.

l High quality temperature sensor (Pt100), more accurate to control temperature, and more endurable.

l Two separate heating coil for top or bottom hot plate, can be individually operated under comprehensive standards.

l 3 group heat blocks can be individually controlled heat and work.

Scorch Sublimation Tester Parameter:

| Model | 605-I | 605-III | 605M |

| l Working position | 1 | 3 | 1 |

| l Heating block size | 50×110mm | 6×6inch | |

| l Heating mode | Scorch: single side heating Sublimation: dual sides heating | ||

| l Temperature range | RT~250℃ | ||

| l Temperature accuracy | ≤ ±2℃ | ||

| l Test pressure | 4kPa±1kPa | ||

| l Timer range | 0-99.99s, 0-99.99min, 0-99.99h, LED display | ||

| l Power supply | AC220V, 50Hz | ||

| l Dimensions (L×W×H) | 550×400×320mm | 680×620×400mm | 600×500×320mm |

| l Net weight | 11kg | 32kg | 15kg |