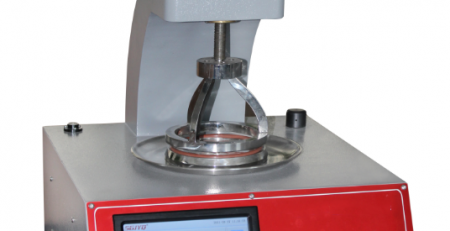

The tensile testing machine is suitable for testing various physical and mechanical properties of plastic sheets, pipes, profiles, plastic films, rubber, wires and cables, etc. For material development, it is an indispensable testing equipment for physical testing, teaching research, quality control, etc. As an important part of the instrument, different materials require different fixtures, which is also an important factor in whether the test can proceed smoothly and the accuracy of the test results.

- Software and hardware: The high-quality tensile testing machine uses a brand computer, and the control system software is the WindowsXP operating system platform. It has the characteristics of fast running speed, mild interface, and simple operation, which can meet the test and measurement needs of different materials. According to national standards, International standards or industry standards measure the physical properties of various materials.

2. Ball screw: The screws currently used in tensile testing machines include ball screws and trapezoidal screws. Generally speaking, the gap of the trapezoidal screw is relatively large, the friction force is relatively large, and the service life is short. At present, some manufacturers on the market will use trapezoidal screws instead of ball screws in order to save costs and obtain greater profits.

3. Motor: The motor of the high-quality tensile testing machine adopts the AC servo speed control system, and the Panasonic AC servo motor has stable and reliable performance. The transformer test has protection devices such as overcurrent, overvoltage, and overload. At present, there is also an electronic universal testing machine on the market that uses ordinary three-phase motors or variable frequency motors. This kind of motor uses analog signal control, which has slow control response and inaccurate positioning. Generally, the speed range is narrow and high speed is not low speed or low speed. There is no high speed, and the speed control is not accurate.

4. Sensor: The sensor is an important part of the precision and stability of the tensile testing machine. At present, the sensor types of the tensile testing machine on the market include S type and spoke type. The accuracy of the internal resistance strain gauge of the sensor is not high, the anti-aging ability of the glue used to fix the strain gauge is not good, and the material of the sensor is not good, which will affect the accuracy of the sensor.

5. Transmission system: There are two main types of transmission parts of the tensile testing machine. One is the arc synchronous gear belt and the precision screw pair transmission; the other is the ordinary belt transmission. The first transmission mode has stable transmission, low noise, high transmission efficiency, high precision and long service life. The second transmission mode cannot guarantee the synchronization of the transmission, so the accuracy and stability are not as good as the first transmission system.

About How to pick the suitable universl testing machine we will introduct in next post

Any more infomation please freely to contact us info@upwelltest.com www.upwelltest.com