During the heating process of the synchronous thermal analyzer, if the measured substance sublimates, vaporizes, decomposes or loses crystal water, the quality of the measured substance will change. At this point, the thermogravimetric curve is not straight, but decreasing. By analyzing the thermogravimetric curve, you can know at what temperature the measured substance has changed and calculate how much weight loss is lost. Below we introduce the application and characteristics of the synchronous thermal analyzer.

The thermogravimetric curve shows that the five crystal waters in copper sulfate 5H2O are removed in three stages. Thermal analysis helps to study changes in crystallinity such as melting, evaporation, sublimation and adsorption. It also helps to study chemical phenomena such as dehydration, dissociation, oxidation and reduction of substances. Thermal analysis can generally be divided into dynamic (temperature rise) and static (constant temperature). The curve obtained by thermal experiment is called thermogravimetric curve (TG curve). The TG curve takes mass as the vertical axis, and the mass decreases from top to bottom. Taking the temperature (or time) as the abscissa, the temperature (or time) increases from left to right.

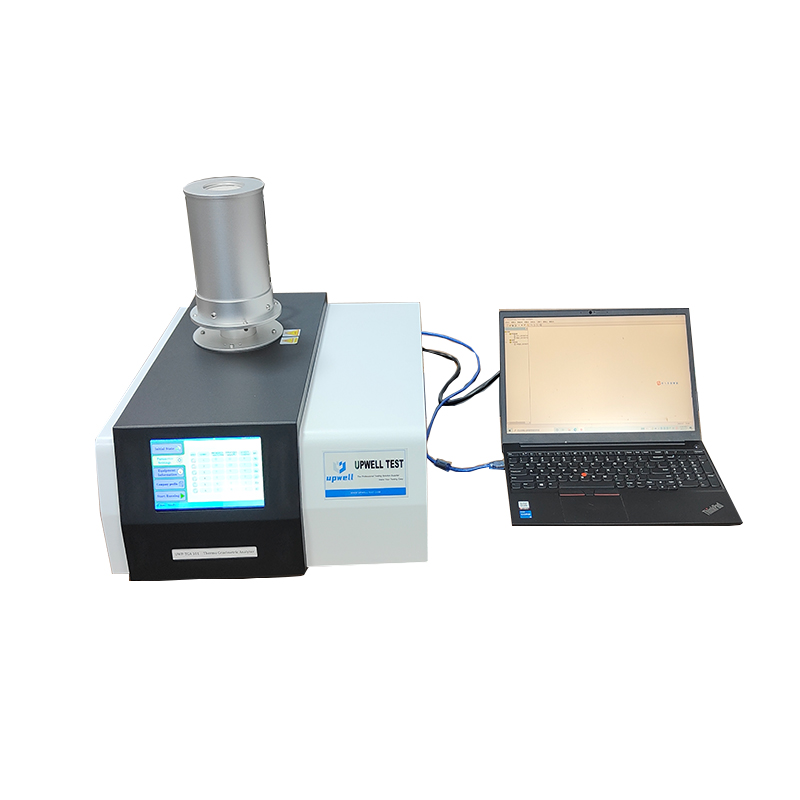

Synchronous thermal analyzer

Synchronous thermal analyzers can measure thermogravimetric and differential thermal information simultaneously. Widely used in ceramics, glass, metals/alloys, minerals, catalysts, energetic materials, plastic polymers, coatings, medicine, food and other industries.

Thermogravimetric analysis can be used to study when the weight of a substance changes when the analyzer is heated. Properties measured by thermogravimetry include corrosion, pyrolysis, adsorption decomposition, solvent loss, redox reaction, hydration dehydration, decomposition, black smoke powder, etc. At present, it has been widely used in the research and development, process optimization and quality control of plastics, rubber, coatings, medicine, catalysts, inorganic materials, metal materials, composite materials and other fields.

The specific analysis of the research of the synchronous thermal analyzer analyzer is as follows

Thermal decomposition of inorganic, organic and polymers; corrosion of metals by gases at high temperatures; solid reactions; roasting and smelting of minerals; liquid distillation and evaporation; determination of moisture, volatiles and ash in the pyrolysis of coal, oil and wood; sublimation; dehydration and hygroscopicity studies of explosive materials; chemical kinetic studies; discovery of new compounds; adsorption and desorption; catalytic activity determination; surface area determination; oxidation and reduction stability studies: reaction mechanism studies.

The synchronous thermal analyzer can study the physical and chemical development and change analysis process of the main materials during the heating process by learning the heat absorption, heat dissipation behavior and weight changes of the materials. This is often one of the fundamental information device techniques in materials management science. The universal synchronous thermal analyzer consists of a heating system, a temperature control working system, a signal amplification system, a differential thermal system and a recording data system.

Any interested please contact us www.upwelltest.com or email info@upwelltest.com