ISO 20344 ISO20568 SAFETY FOOTWEAR COMPRESSION & PUNCTURE TESTER

- Description

- Inquiry

Introduction:

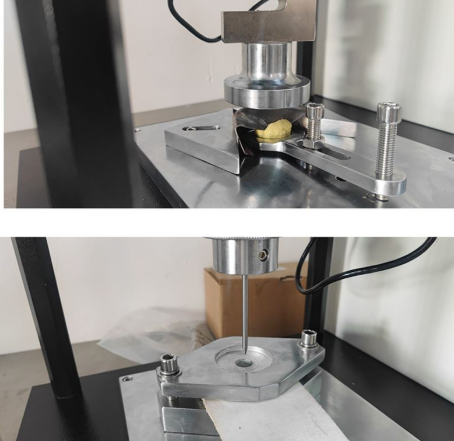

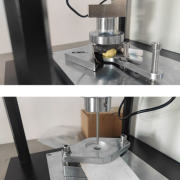

A: (static pressure test): The toe of the shoe is tested by the tester at a constant rate until the pressure value reaches the specified value, and the lowest height value of the sculptured clay cylinder in the test toe is measured, and the size is used to evaluate the compression resistance of the toe of the safety shoe or protective shoe.

B: (puncture test): The tester drives the puncture nail to puncture the sole at a certain speed until the sole is completely punctured or reaches a certain specified force. The maximum force required for the sole to be completely punctured or the puncture nail is exposed when a certain specified force is reached to evaluate the anti-puncture performance of the safety shoe, protective shoe or occupational shoe that prevents puncture of the midsole.

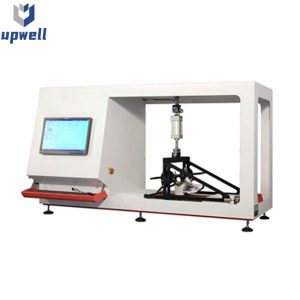

Function:

The computer system safety shoe pressure and puncture tester is mainly used for the pressure resistance test of the toe of the safety shoe. The instrument continuously presses the fixed toe at a speed of 5mm/min, such as: 15000N for 1 minute. In addition, the replaceable fixture is used for the puncture test of different standards of the midsole materials of safety shoes. The sample is fixed on the fixture and the sample is punctured or zero punctured at a speed of 10mm/min to evaluate the maximum nail puncture force that the material can withstand.

Comply Standards:

GB/T20991-2007, ISO EN 20344-2007, CSA-Z195, ASTM F2413-2005, BS-953, GB21148-2007, ISO 22568 and other standards.

Parameter:

Speed range | 5mm/min、10mm/min、25mm/min、MAX Stepless Speed Regulation Stepless control |

Capacity(optional) | 2000kgf |

Load | Sensor 1:2000kg Sensor 2:200kg |

Unit | kg、N、Ib |

Test mode | Withstand pressure and puncture |

Power | AC220V,50/60Hz,400W |

Size(W×D×H) | 710×330×620mm |