ASTM D 2596 ASTM D 2266 ASTM D 2783 Four Ball Wear Tester Wear Spot Measuring System

This is a powerful and professional two-dimensional microscopic image measurement software. Full Chinese interface, simple operation, easy to master, can realize real-time image acquisition, capture, real-time analysis, storage, editing, measurement and offline processing, with versatility and scalability.

- Description

- Inquiry

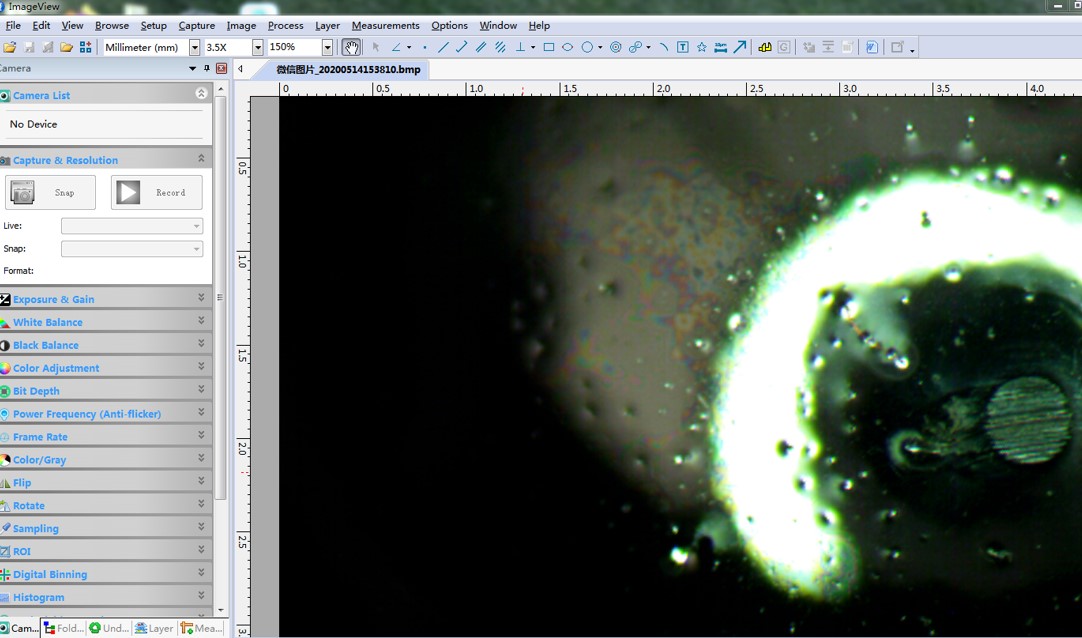

The main machine adopts the base cantilever beam structure, the base is horizontal, and the four-ball oil box and other sample holding devices are placed on the base; the camera is fixed on the upper end. Such a structure can make the observation axis of the lens barrel perpendicular to the plane where the steel ball wear spot is located, ensuring the authenticity and accuracy of the observation data.

This is a powerful and professional two-dimensional microscopic image measurement software. Full Chinese interface, simple operation, easy to master, can realize real-time image acquisition, capture, real-time analysis, storage, editing, measurement and offline processing, with versatility and scalability.

Four Ball Wear Tester Wear Spot Measuring System

Main functions:

- Real-time collection and photographing of microscopic images

- Calibration of microscopic images, display scale, measurement (including measurement of length, angle, radius, concentric circle radius, etc.)

- Storage and output of microscopic images

Auxiliary function:

- Color adjustment and optimization of microscopic images

- the display size adjustment of the microscopic image

- Query of magnification of microscopic image

- Area selection and cropping of microscopic images

- Text labeling of microscopic images

- Open the saved image for editing