Fabric Textile One way Transmission Capability

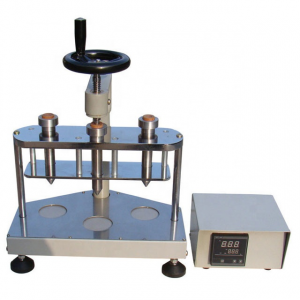

Automatic Fabric Textile One way Transmission Capability for Sportswear fabric testing, underwear fabric testing, comfort testing.

The absorption and diffusion of sweat by fabrics directly affects the comfort performance of clothing. Testing this performance is particularly important, especially for sports fabrics. Currently, AATCC 195 and GB/T 21655.2 have defined how to test the transfer characteristics of sweat in fabrics. 290B fully meets the test standards and is used to measure the overall dynamic performance of liquid in knitted fabrics, mainly testing the following aspects:

- Description

- Inquiry

Automatic Fabric Textile One way Transmission Capability FOR Sportswear fabric testing, underwear fabric testing, comfort testing.

The absorption and diffusion of sweat by fabrics directly affects the comfort performance of clothing. Testing this performance is particularly important, especially for sports fabrics. Currently, AATCC 195 and GB/T 21655.2 have defined how to test the transfer characteristics of sweat in fabrics. 290B fully meets the test standards and is used to measure the overall dynamic performance of liquid in knitted fabrics, mainly testing the following aspects:

1. Absorption speed-moisture absorption time on the front and back of the fabric

2. One-way transfer capacity-the difference in liquid absorption and diffusion on two sides

3. Spreading/drying speed-the spreading speed of liquid on both sides of the fabric

Feature:

1. The shell is all metal structure, which has good anti-interference ability against external interference signals.

2. The up and down movement of the test sensor is changed from manual to automatic. The upper sensor is driven by a stepping motor and has a built-in pressure detection device. It automatically stops when it moves to a fixed pressure and returns automatically after the test.

3. The pump structure is improved, the pump water is uniform and stable, and the pump water volume can be adjusted by software. The pump can reverse rotation to pump the salt water in the pipe back to the storage tank to prevent the salt water crystal from clogging the pipeline.

4. Wireless WiFi connection to the computer, data transmission is more stable and reliable.

Main Parameter:

1. Test environment: 18℃~40℃, 20%~80% (non~condensing)

2. Pumping time: 20sec

3. Delivery volume of test liquid: 0.2g+/-0.01g (the user can fine-tune)

4. Test liquid conductivity: 16mS+/-0.2mS

5. Test pressure: 960grams

6. Communication interface: wireless wifi

7. Dimensions: 200×360×250mm

8. Weight: 12kg

9. Power source: 110V~230V 50Hz/60Hz 0.5A

Test Principle

The instrument contains a pair of upper and lower multi-ring resistance measuring probes; the stepping motor drives the upper sensor to horizontally press the sample on the lower transmitter with a fixed pressure, and then it takes 20 seconds to uniformly 0.2 g of the standard test solution Transported to the surface of the sample for testing; the computer can dynamically record the changes in the resistance of each ring of the upper and lower sensors, and obtain the various parameters we need through standard calculation formulas.

The instrument can measure the following parameters:

1. Wetting time of upper/lower layer (WTT/WTB)

2. Upper/lower suction speed (TAR/BAR)

3. Upper/lower diffusion radius (MWRt/MWRb)

4. Diffusion speed of upper/lower liquid sweat (TSS/BSS)

5. Accumulate one-way transfer capability (R)

6. Overall liquid water absorption and diffusion capacity (OMMC)