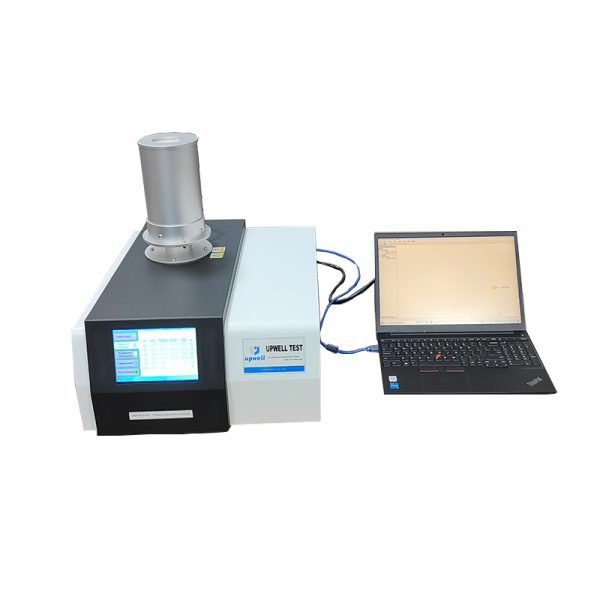

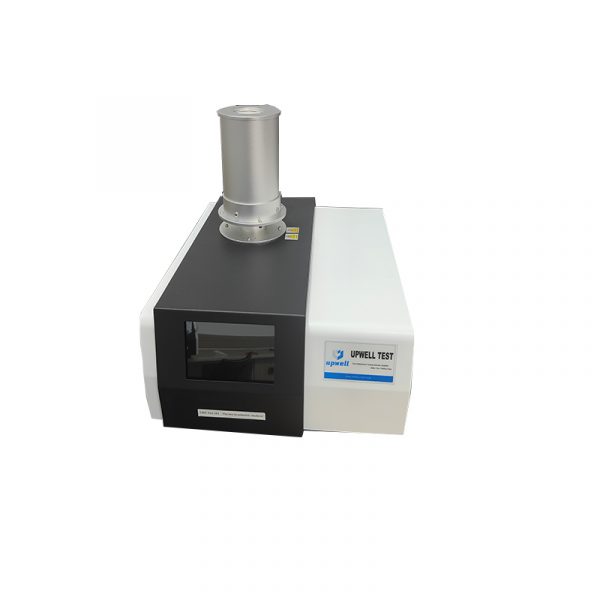

TGA/TG Thermal Gravimetric Analyzer

Thermo gravimetric analyzer (TGA) is in TG, temperature, the temperature or cooling process, observe the quality with temperature or the change of time, the purpose is to study material thermal stability and components. Widely used in plastic, rubber, coating, drugs, catalyst, inorganic materials, metal materials and composites fields of research and development, optimizing process and quality control

Measurement and research material following characteristics:

Thermal stability, decomposing process, adsorption and adsorption, oxidation and reduction, ingredients quantitative analysis, additives and filler influence, moisture and volatiles, reaction kinetics.

- Description

- Inquiry

Thermo gravimetric analyzer (TGA) is in TG, temperature, the temperature or cooling process, observe the quality with temperature or the change of time, the purpose is to study material thermal stability and components. Widely used in plastic, rubber, coating, drugs, catalyst, inorganic materials, metal materials and composites fields of research and development, optimizing process and quality control

Measurement and research material following characteristics:

Thermal stability, decomposing process, adsorption and adsorption, oxidation and reduction, ingredients quantitative analysis, additives and filler influence, moisture and volatiles, reaction kinetics.

Structural advantage

- The furnace body is heated by double-row winding of precious metal platinum wire, which reduces interference and is more resistant to high temperatures.

- The tray sensor is made of precious metal platinum and rhodium wire, which has the advantages of high temperature resistance, oxidation resistance, and corrosion resistance.

- Separate the power supply and the circulating heat dissipation part from the main unit to reduce the influence of heat and vibration on the micro-thermal balance.

- Adopt top-opening structure, easy to operate. It is difficult to move the furnace body up to place the sample, and it is easy to cause damage to the sample rod.

- The host adopts to isolate the thermal influence of the heating furnace body on the chassis and the micro-thermal balance.

- The furnace body can be replaced according to customer requirements

Controller and software advantages

- Using imported ARM processor, sampling speed, processing speed is faster.

- Four-way sampling AD collects TG signal and temperature T signal.

- Heating control adopts PID algorithm for precise control. Multi-stage heating and constant temperature

- USB two-way communication is adopted between the software and the instrument, which fully realizes remote operation, and the parameter setting of the instrument and the operation and stop of the instrument can be carried out through the computer software.

- 7-inch full-color 24bit touch screen, better man-machine interface. TG calibration can be achieved on the touch screen

Technical parameters:

| Temperature range | Room temperature ~1150℃ |

| Temperature resolution | 0.01 ℃ |

| Temperature fluctuation | ±0.01℃ |

| Heating rate | 1 ~ 100 ℃ / min |

| Temperature control mode | Rising, Constant temperature |

| Balance measuring scope | 0.01mg~3g (Can be extended to 30g need custom) |

| Resolution | 0.01mg |

| Constant temperature and time | 0 ~ 300min (set arbitrarily) |

| Display | liquid crystal display (LCD)and computer display, English version |

| Atmosphere | inert, oxidizing, reducible, static and dynamic |

| Atmosphere device | Built-in gas flow meter, includs switch two path gas and control flow volume |

| Software | record TG curves automatically, Processing data and print Software with multi-point correction function, high and low temperature test more accurate |

| Data interface | USB interface |

| Power | AC220V 50Hz |