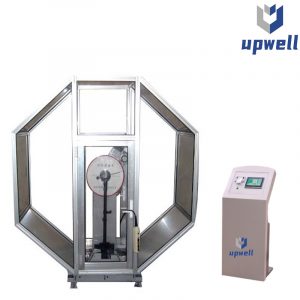

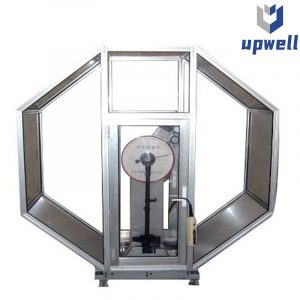

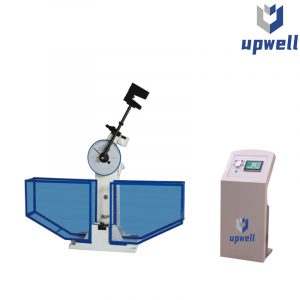

Acceleration Mechanical Shock Test Machine/Acceleration Impact Testing Machine

Acceleration Mechanical Shock Test Machine/Acceleration Impact Testing Machine It is mainly used in the research and production of aerospace, aviation, ships, weapons, electronics, automobiles and other industrial fields to assess the impact resistance of products. It is suitable for testing the impact test of devices, components and complete machines with large impact acceleration. IS is a fully automatic mechanical shock test system, used to measure and determine the impact resistance of products or packaging. IS can perform conventional half-sine wave, square wave, sawtooth wave and other waveform impact tests to realize the product in the actual environment. Suffered shock wave and shock energy, so as to improve the system or optimize the product packaging structure

- Description

- Inquiry

Acceleration Mechanical Shock Test Machine/Acceleration Impact Testing Machine It is mainly used in the research and production of aerospace, aviation, ships, weapons, electronics, automobiles and other industrial fields to assess the impact resistance of products. It is suitable for testing the impact test of devices, components and complete machines with large impact acceleration. IS is a fully automatic mechanical shock test system, used to measure and determine the impact resistance of products or packaging. IS can perform conventional half-sine wave, square wave, sawtooth wave and other waveform impact tests to realize the product in the actual environment. Suffered shock wave and shock energy, so as to improve the system or optimize the product packaging structure

Feature:

- This series of products adopts automatic lifting, free impact, high preset, high impact energy, easy operation, safe and reliable.

- Impact test bench is based on the window, the automatic impact test system of the operating system, and the friendly control interface. The operator simply inputs the test data, the system will automatically configure the parameters and control the machine to accurately complete the impact test. The shock acceleration, pulse duration, and pulse velocity changes are displayed on the display screen after being controlled and measured by the measuring instrument

- Equipped with anti-secondary impact braking device; the impact table falls freely and when the impact wave pad rebounds, the hydraulic brake piston action impacts the table to be braked, no second impact occurs, and the impact data is accurate.

- It has a high-efficiency platform vibration damping device; for a large impact test bench, the instantaneous impact force is very large during an impact test. The high-efficiency platform vibration damping device greatly reduces the impact on the ground. It does not require a special foundation and is very installed. Convenience.

- The impact height is digitally set, and the impact table automatically rises to the set height, with high control accuracy and good impact data repeatability.

- The impact measurement system is equipped to display the impact energy data and waveform in real time.

- It can be equipped with a high acceleration generator. For small specimens, high acceleration shock tests are required. The high acceleration generator can be fixed on the surface of the shock test bench. According to the principle of shock kinetic energy transmission, higher shocks can be obtained than IS type shock tables. Acceleration, for the specimen with a specimen smaller than 200×200mm, the impact test index is: the peak acceleration of impact can reach 5000-50000m/s2, and the acceleration duration is 0.2-1ms.

Parameter

| Model | UWI-003 |

| Max. Loading Capacity | 5kg |

| Pulse Wave | Half sinusoidal wave |

| Shock Impact Peak Acceleration | Half sinusoidal wave:100~30000m/s2 |

| Pulse Duration Time | Half sinusoidal wave: 0.2~20ms |

| Impact Frequency | 1~8000Hz |

| Bench Dimension | 120mm×120mm |

| Max. Drop Height | 1500mm |

| Machine Weight | 1300kg |

| Power | 220V±10% 1 Phase 50Hz |

| Power Consumption | 2.5KVA |

| Anti-secondary shock advice | Air Friction Braking Device |

| External Dimension(Host Body) | 900mm×450mm×2700mm |

| Working Condition | Environment Temp. : 5℃-40℃ |

| Relative Humidity: ≤90%(25℃) |