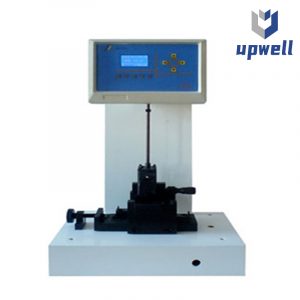

ISO 1133, ASTM D 1238, ASTM D 3364 Automatic MFR MVR Plastic Melt Flow Index Tester

Melt flow rate meter is in the specified temperature conditions, with high-temperature furnace to melt the state of the measured object. The molten state of the measured object, the required weight load by gravity out of a certain diameter hole in the test. Plastics in industrial enterprises and scientific research units of production, often with “melt (mass) flow rate” to represent the polymer material in the molten state of fluidity, viscosity and other physical properties. Melt flow rate refers to the extrudate, the average quality of the sample paragraphs are translated into 10 minutes of extrusion volume. Melt (mass) flow rate expressed by MFR, unit: g / 10 minutes (g / min)

- Description

- Inquiry

Melt flow rate meter is in the specified temperature conditions, with high-temperature furnace to melt the state of the measured object. The molten state of the measured object, the required weight load by gravity out of a certain diameter hole in the test. Plastics in industrial enterprises and scientific research units of production, often with “melt (mass) flow rate” to represent the polymer material in the molten state of fluidity, viscosity and other physical properties. Melt flow rate refers to the extrudate, the average quality of the sample paragraphs are translated into 10 minutes of extrusion volume. Melt (mass) flow rate expressed by MFR, unit: g / 10 minutes (g / min)

Test Standard :

ISO 1133, ASTM D 1238, ASTM D 3364

Feature:

1.English LCD Touched Screen.Ø

2.Hand automatic cutting material.

3.Double temperature control system, temperature control precision is more accurate, higher heating efficienc

4.Double imported sensors, more accurate temperature gradient from top to bottom, can be used independently, and improve the service life.

5. Cylinder for imports hartz alloying nitriding treatment, opening mould for carbon tungsten steel material, material reality.

6.Insulation barrels of sus304 stainless steel material for the whole, long-term high temperature does not rust.

7.Automatic calculation results, and print.

Technical parameter:

1. Temperature range: room temperature -450℃

2. Temperature drift: 4 hours≤0.5℃

3. Temperature fluctuation: ±0.2℃

4. 10mm-70mm above the die

5. Temperature uniformity: ±1℃

6. Temperature display resolution: 0.1℃

7. Time display resolution: 0.1S

8. Cutting timing range: 1-999S adjustable

9. Die diameter: Φ2.095±0.005mm (half die 1.05mm+0.005, optional)

10. The length of the discharge port: 8.000±0.025mm

11. Piston rod diameter: 9.474±0.007mm

12. The length of the piston rod: 6.35±0.13mm

13. Diameter of charging barrel: Φ9.550±0.007mm

14. Test range: 0.1-300g/10min

15. Weight accuracy: ±0.5%

16. Cutting method: manual and automatic cutting

17. Operation mode: button control

18. Test load: a total of 8 levels, 8 sets of weights

19. Power supply voltage: AC220V±10% 50HZ