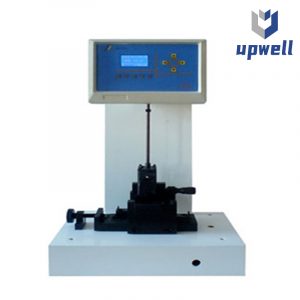

Laboratory Open Mill Rubber Mixing Machine

- Description

- Inquiry

Introduction:

Laboratory Open Mill Rubber Mixing Machine Used in the production of chemical raw materials, rubber, silica gel, etc., as well as polymer blending, mixing of pigments, stabilizers, stabilizers, etc., color matching, mixing of raw rubber and compounding agents, or rubber hot mixing and rubber tableting.

Feature:

- Construction of mill rolls: drilled roll, bored roll, grooved roll

- We can design speed ratio as per customers’ formula and processing requirements.

- Frame, frame cap and base are welded and treated by annealing for stress relieving.

- Rolls material is chilled cast alloy iron which hardness is reach to 70HB.

- Brake and emergency stop device can ensure the safety of personnel and equipment.

- Auto feeding oil or grease lubrication, it is easy to maintain and protect machine.

- Human nature designed controlling system ensure labor safety.

- Methods of adjusting roll nip: manual or electric

Parameter:

- Mixing capacity: 2-60g

- Drum temperature: normal temperature ~ 300℃

- Heating method: electric heating (new process design, electric heating of open mill drum, automatic constant temperature)

- Temperature accuracy: ±2℃ (The thermostat adopts a high-precision PID intelligent microcomputer control system, with an internal constant automatic calculation function, which is more accurate than manual setting and saves time. It has an over-temperature function to protect machinery and production materials)

- Drum speed: 0-19 rpm adjustable

- Roller speed ratio: 1:1.25 (speed ratio can be customized according to customer needs)

- Roller size: ф76mm×L 300mm (high hardness surface hard chrome plating, no sticking, no delamination)

- Roller spacing: 0.1~5mm adjustableProtection device: Multiple touch-type emergency stops (with reverse function, humanized design, no work-related injuries to operators)

- Motor: 0.3KW 1 set (new process design, mechanical structure adjustment, the output torque is as large as the traditional process mechanical transmission 1KW, achieving the purpose of energy saving)

- Power: 1KW

- Volume: (W×D×H) 1100×400×1180mm. The volume is smaller than that of traditional processes with the same functions.

- Roller lubrication: The excellent wear-resistant bearing contact area and traditional copper sleeve extend the service life by 2/3.

- Mechanical structure: steel plate (lighter weight, smaller volume, higher mechanical strength and better toughness than traditional cast iron)

- Power supply 5∮, AC380

- Weight: about 160kg